Hey Everyone. I want to start by saying it has been a pleasure working with everyone in the maple syrup community over the last years. Developing my line of equipment has been a challenge and rewarding task. This last year was a great year for us, and by how the weather turned out it sounds like it was a good season as well.

As some know from previous posts, I work full time as a welder at a local manufacturing business. Managing Wegner Metal Works which has turned into an almost full time job in itself, working full time, and trying to properly fulfill my role as a husband and father has been getting harder by the year. My wife and I sat down and looked over all the details and decided that it would be best for our family if we closed. It was a difficult decision to close something that was running so well and that I worked so hard to get established. I think the long term effects will be far more positive this way, than having a few more dollars in the bank at the end of the year.

God has always provided for us and will continue to in the future however He sees fit.

Psalms 37:23-24 23The steps of a good man are ordered by the LORD: and he delights in his way. 24Though he fall, he shall not be utterly cast down: for the LORD upholds him with his hand.

Thank you for all the kind words of support and for choosing Wegner Metal Works as your equipment choice. I may pick this back up after the kids are in college or older so you may see them again in the future!

Andy Wegner

Wegner Metal Works LLC

WEGNER METAL WORKS

And whatsoever ye do, do it heartily, as to the Lord.. Col. 3:23

Monday, April 22, 2013

Friday, November 9, 2012

Special size pans

We have 9 custom dimension type pans available. They measuer 19.5"w x 37.5"l x 12"h. The material is our typical 22ga polished stainless. The seams are TIG welded as usual, and can have fittings welded per your request. These would work great for either a large finishing unit or evaporator pan. They also come with a lid to cover your contents. I originaly posted a price of $400 and would be willing to lower to $375 for pan with lid + fitting of your choice and location. Might be open to offers. $75 for filter tray. Contact me to get one!! 920-660-6646 or by email andy@wegnermetalworks.com.

Sunday, September 23, 2012

Getting ready and some exciting updates

Its been a while since my last post....sorry. Alot has been going on in the shop this last couple months. That and having a busy family we needed to take some time to enjoy the summer weather and the outdoors. Its time to get a move on with equipment and ground myself..not literally because taking a shock from a TIG welder hurts and would prefer the table to be the path to ground... :-)

Anyhow. One hard decision we had to make this season was that of how to approach it. Being that I still do work a full time job at a local manufacturing facility we did from time to time hire friends to help during the busy times. Several factors played into our decision, but my wife decided she would like to take a more active role at WEGNER METAL WORKS. She put her career on the back burner and is working as a team with me. For now she is doing mostly prep work, finishing, and shipping. I will remain the welder/fabricator while she takes on some logistics, accounting and various secretarial duties. She and I are very excited to now be more focused on the same goal.

The last couple weeks have been dedicated to getting caught up on orders and get our inventory of hydrometer cups built.

Also, didnt want to say too much until it actually happened. There will be some new products "rolling" out of our shop. Blitz Cycleworks is the new handmade bicycle frame builder in Green Bay. I took a couple week trip to the west coast for a framebuilding course. The first Blitz bike was born there. I will be specializing in Titanium handmade cycles. Steel is always a more economical option too.

Anyhow. One hard decision we had to make this season was that of how to approach it. Being that I still do work a full time job at a local manufacturing facility we did from time to time hire friends to help during the busy times. Several factors played into our decision, but my wife decided she would like to take a more active role at WEGNER METAL WORKS. She put her career on the back burner and is working as a team with me. For now she is doing mostly prep work, finishing, and shipping. I will remain the welder/fabricator while she takes on some logistics, accounting and various secretarial duties. She and I are very excited to now be more focused on the same goal.

The last couple weeks have been dedicated to getting caught up on orders and get our inventory of hydrometer cups built.

My first Titanium build. Custom geometry 29er to fit me. Sram X9 2x10 parts group, Rock Shox Reba RLT fork. Chris King headset. A nothing special stock set of DT Swiss wheels with Tubless tires. The frame weighs in at 3lbs 8oz. Weight with steel pedals and heavy wheels is 25lbs. Could easily be lighter with some carbon upgrades. I raced it last weekend and finished the 40 mile 4,000 ft climb, course 14 minutes faster than last year. I'm in love with the smooth and light ride a Ti bike has to offer.

If you are a cyclist or would just like to check out what's going on at Blitz Cycleworks you can follow on Facebook. https://www.facebook.com/BlitzCycleworks. I'll be ready to accept frame orders in the next month. Still getting equipment installed and misc pieces ready to go.

Sunday, May 27, 2012

LIVESTRONG FOUNDATION

Last year I had the opportunity to ride in the Tour de Road America

For the last few years I was able to make a donation to the LIVESTRONG foundation through the Tour. Riding as many laps on the beloved track Road America!! This year I would like to raise $2,000 to support the foundation.Follow this link if you would like to contribute to the foundation. LIVESTRONG GRASSROOTS FUNDRAISER. All donations made will be matched by a generous donor until 5/31/12!! TWICE AS STRONG!!!

A little history in from my family. Shortly after my wife and I were married my grandmother was diagnosed with cancer. She lost her battle a few years later. I also have an aunt who was diagnosed with cancer and also lost her battle a couple short years later.

Since that time I have had several family members and friends who have won their battles with cancer and some who have, unfortunately, lost. Cancer is now the worlds leading cause of death. However every year the technology that is being developed is helping prevent, or cure cancer like never before. Please consider making a donation today!!

For the last few years I was able to make a donation to the LIVESTRONG foundation through the Tour. Riding as many laps on the beloved track Road America!! This year I would like to raise $2,000 to support the foundation.Follow this link if you would like to contribute to the foundation. LIVESTRONG GRASSROOTS FUNDRAISER. All donations made will be matched by a generous donor until 5/31/12!! TWICE AS STRONG!!!

A little history in from my family. Shortly after my wife and I were married my grandmother was diagnosed with cancer. She lost her battle a few years later. I also have an aunt who was diagnosed with cancer and also lost her battle a couple short years later.

Since that time I have had several family members and friends who have won their battles with cancer and some who have, unfortunately, lost. Cancer is now the worlds leading cause of death. However every year the technology that is being developed is helping prevent, or cure cancer like never before. Please consider making a donation today!!

Monday, April 16, 2012

Now what!?

Well as everybody experienced, it was a very short season. We didn't produce much syrup at all... A little disappointing but was a good R&D year for us with the equipment. Time to clean up the shop and start working on next year's products. Being that I spent so many hours in the shop and working during the winter... I need something to get back in shape right?

Well this early warm weather has proven to be quite accomidating to my other favorite activity.... Cycling.Riding on a local team, the Titletown Flyers, puts me back to race diet and plenty of saddle time.

This weekend a few of us will be biking a 100 mile race called the Dairy Roubaix and will be a challenge. Mostly on gravel and maintanance roads, I will be riding my Cyclocross bike(pictured). WORS is the big Wisconsin off road racing series and will be doing a few of those. The ones I'm really excited about are the Wausau 24 hr race and the Chequamegon Fat Tire 40.

This year I am working on making and racing my own bicycle frames. Starting with chromoly until I finish my Titanium tig course in August. Then will be making custom Titanium and Chromoly frames.

Well this early warm weather has proven to be quite accomidating to my other favorite activity.... Cycling.Riding on a local team, the Titletown Flyers, puts me back to race diet and plenty of saddle time.

This weekend a few of us will be biking a 100 mile race called the Dairy Roubaix and will be a challenge. Mostly on gravel and maintanance roads, I will be riding my Cyclocross bike(pictured). WORS is the big Wisconsin off road racing series and will be doing a few of those. The ones I'm really excited about are the Wausau 24 hr race and the Chequamegon Fat Tire 40.

This year I am working on making and racing my own bicycle frames. Starting with chromoly until I finish my Titanium tig course in August. Then will be making custom Titanium and Chromoly frames.

As of now I am getting tooling and parts to complete my first frame. So kind of taking things as they go.

Saturday, February 18, 2012

Let it begin!!

Some of our plans have changed and we didnt have much time to get our things together. We are tapping our own trees this year, instead of just helping out on others. I couldnt decide which heat source I wanted to go with, propane or wood. We are only doing 20 taps and aren't going too crazy. I did end up deciding this week we are doing wood and made a simple cinder block arch today. If we had known all along that we would be tapping our own trees. I would have made myself one of the sweet arches that I made for sale last year. We tapped yesterday and checked this afternoon. Not much doing but weather wasn't prime either. We ended up with a gallon or so of sap so nothing worth cooking. We did want to do a test boil on the arch to see how it was and what we need to tweak before the real stuff is on. We had a good boil in about 25 minutes and hard boil in 30-35. This being said, I am not the best fire starter and some of that time was me trying to get the fire going. Gasket for the top is in order this week. Flue slots on the front plate, and dividers in the pan are also called for. Overall I'm satisfied with the start and look forward to the fun we will have this season.

Saturday, February 11, 2012

Shop pics

A good friend of mine designed this label for me and we just received them back from printing. We are excited to have these on our pans from now on!!

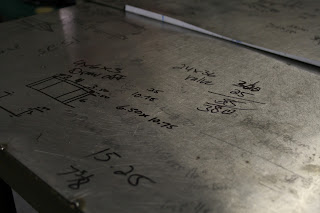

I got this idea from another blog of a fabricator who also works with stainless. Thought the concept was great. Saves paper, laquer thinner wipes it clean.

This pan is for the same friend who designed the logo. He is a photographer and I thougt he would like the perspectives and abstract pics of this phase of the pan. Its a 3 x 4 continuous flow pan with a draw off box.

I got this idea from another blog of a fabricator who also works with stainless. Thought the concept was great. Saves paper, laquer thinner wipes it clean.

This pan is for the same friend who designed the logo. He is a photographer and I thougt he would like the perspectives and abstract pics of this phase of the pan. Its a 3 x 4 continuous flow pan with a draw off box.

Subscribe to:

Posts (Atom)